Health & Safety: Mitigating Asphyxiation Risks

Building Awareness to Avoid Unnecessary Risks and Protect Workers

Understanding the Properties of Gases

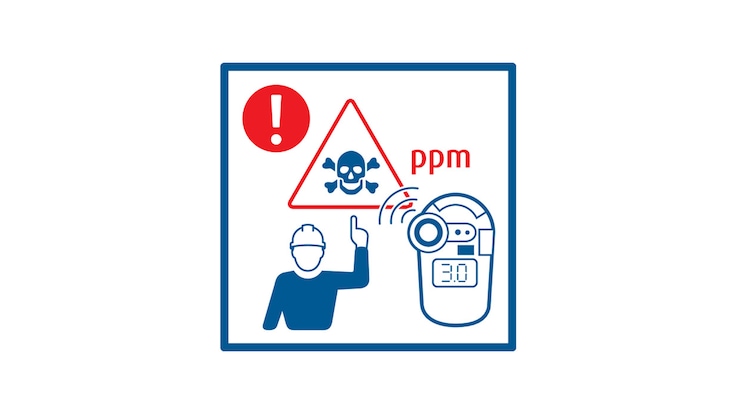

As gases are often invisible and odorless, their potential to cause harm is often underestimated. In fact, the risk of asphyxiation is one of the greatest hazards associated with nitrogen and other inert gases such as argon, carbon dioxide and helium. This means they displace and dilute oxygen and people can suffocate as a result.

Most asphyxiation incidents occur because workers enter vessels or confined spaces connected to an inert gas supply before checking the oxygen concentration in the air.

Training Matters

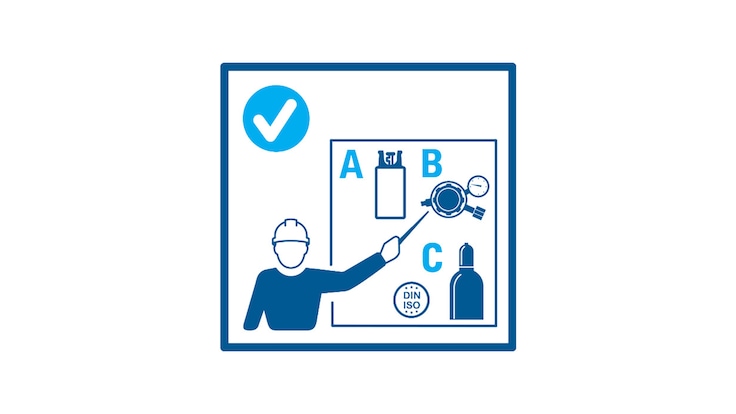

At Linde, we are committed to helping our customers protect their employees against the risk of asphyxiation. All good safety practices start with information and training. Before even starting work, your employees must be informed about potential risks and trained in safety-aware procedures, including appropriate practices for entering confined spaces. The right work permits are also essential. To help you get your staff up to speed, we have developed a range of useful training materials.